Good morning Stijn, I hear LCV is doing well! Tell me, how did it all start?

"Laser Cladding Venture was launched in 2015 as a

spin-off of the Flemish Institute for Technological Development (VITO). In the

beginning there were 3 of us but in the meantime our tightly-knit team counts 9

employees."

How is laser cladding employed in LCV?

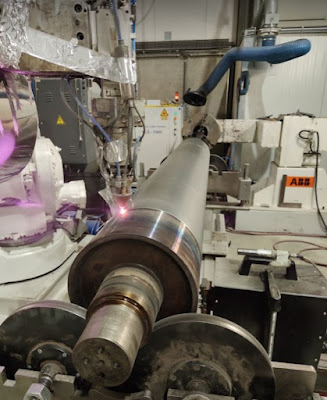

"Laser

cladding (or laser metal deposition) is a welding process where a laser creates

a molten pool on the target surface. A metal-containing filler material (powder

or wire) is then melted into the substrate. Traditionally, this process was

used to repair turbine shafts and similar items. What makes laser cladding

appealing is the minimal heat input.

Today LCV

aims to evolve laser cladding into industrial series production. Here we

focus mainly on applying coatings to new pieces and sometimes on refurbishing

in series production. Laser cladding coatings extend the life of equipment,

reducing the need for ad hoc repairs. The philosophy behind this is to

cost-competitively apply a coating at an industrial level that provides a

longevity extension.

LCV provides coatings via laser cladding for, among others:

- Hydraulics (large piston rods)

- Process industry

- Steel industry

- Compacting and earthmoving

LCV operates a technique that is slightly different from the classic powder bed process. How does this work exactly?

"The powder bed method involves applying layers of powder to a plate and, layer by layer, you proceed to melt where you want the powder to be. At LCV, we blow the powder into the laser light very focused through a nozzle.

This

technique is interesting because you can work on larger areas and more

hybrid which also allows you to treat more complex surfaces. That is

why we use it as a coating technique because of its flexibility."

In laser cladding you can use either wire or powder. Why does LCV prefer to use powder?

"Powder

comes in many more varieties so we have more liberty in the development

of alloys, compositions and gradients. In addition, we can also switch powder

during the process and powder is also in fact still easier to melt with the

laser. Wire requires more heat input which can be a disadvantage to the

resulting properties of the material."

What makes your welding process so unique?

"We apply

a laser source so there is less heat input. This results in less

distortion and a harder microstructure: typically 20% harder and 4x more

wear resistant. Also, it requires less material because not as much

material from the substrate is mixed in. There are typical criteria for the

highest permissible level of mixing from a corrosion perspective.

Thermal

spray coatings (such as ceramic coatings for piston tanger) are only mechanically bonded

therefore they are not impact resistant. Consequently, when the coating is

damaged, the underlying material is exposed with an increased risk of

corrosion.

Our welding

process results in a metallurgical, and therefore better, bond while we can

also guarantee good corrosion properties thanks to the low mixing."

As the name suggests, laser cladding is the focus but you are also working on 3D printing in addition to surface coatings. Will this assume an equally important position as cladding coatings for LCV?

“Coatings

cladding still remains our core business. At VITO we were already doing a bit

of 3D printing with laser cladding. While it was then primarily about

characterization of material properties, now the focus is more on developing

the 3D printing process in order to be able to use it at an industrial level.

How do you see your place within the 3D printing landscape?

"Traditionally,

3D printing has the advantage of greater design versatility. The

additional design capabilities make it easy to eliminate material in the design

where it is not needed. Think of the aerospace sector where one can make more

complex structures that are much lighter.

However, we

do believe that we have our own unique place within this landscape. Our

resolution, unlike that of other companies, is more in the range of cast

pieces with simple geometry. For example, for one customer, we were able to

reduce the production lead time from 3 months to 1 month by shifting from

a casting process to 3D printing by laser cladding. As icing on the cake, we

obtained better material properties (harder and more wear resistant), less

material loss during the process and a lower cost.

How have the applications evolved over time?

What is the main challenge regarding material properties in this process?

"Thermal

tensions from the welding process can cause the pieces to warp and crack. Heat treatment helps to relax these stresses.

When certain pieces have dimensional tolerances, they are typically re-milled

but as a result of internal stresses, they can start to move during the milling

process so that the dimensional tolerances no longer quite match.

Are there any specific tests that LCV performs or has performed on laser cladding coatings or samples?

"For

additive manufacturing, we get samples verified to identify microdefects in

the material. These have an influence on the mechanical properties of the

products. In the future, we want to rely on the expertise of METALogic for this

matter because we can count on a convenient lead time that we have already

experienced in previous projects.

There are

also several standard tests that we have performed on overlay welds and hard

facings. We typically apply these layers as a coating to create more

corrosion resistance or wear resistance. We do this according to certain

standards. There are a number of tests

mentioned in ISO and ASME standards (ISO 15614 & ASME_IX) such as measuring

hardness, composition, measuring admixture,...

Concerning

corrosion resistance, there is ASTM G28 to test the resistance to intergranular

corrosion. If the results of this are not satisfactory, the reason is typically

that the microstructure is not adequate. Possible causes can be, for example, too high

temperatures during welding or too rapid solidification of the material."

Stijn, thank you for your time and elaborate answers!

Be sure to take a look at the LCV website for more information! METALogic is of course also at your service as an expert in testing the corrosion resistance of welds, the characterization of (3D printed) materials and offers you a solution for all kinds of corrosion related issues.